Resource Recovery-Based Solution for Rubber and Plastic Waste

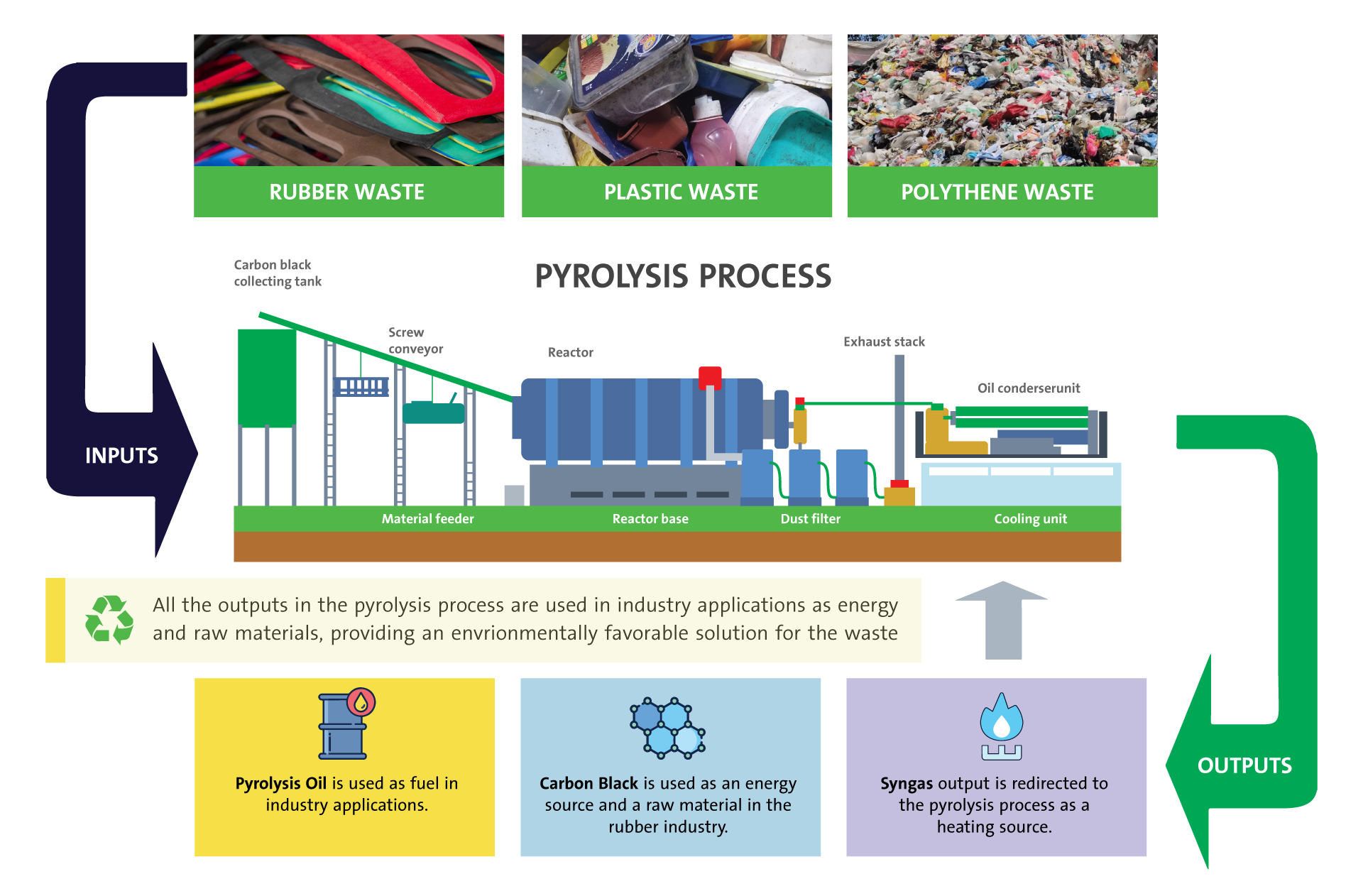

With the global economic and industrial improvement, countless amounts of rubber and plastic waste are generated every day and released into the natural environment. Decomposition of rubber and plastic waste can take hundreds of years and is accompanied by leaching of a number of toxic organic compounds into the soil. However, most of the old plastic and rubber waste are stored in landfills, buried in the ground, or burned. All these methods are not environmentally friendly.

Resource Recovery-Based Total Solution for Rubber and Plastic Waste

INSEE Ecocycle, the pioneer in sustainable industrial waste management in the country, has further expanded its resource recovery-based waste management solution to serve Sri Lanka’s rubber industry with an advanced pre-processing mechanism called Pyrolysis with the capacity of 1800 Mt per annum.

What is Pyrolysis?

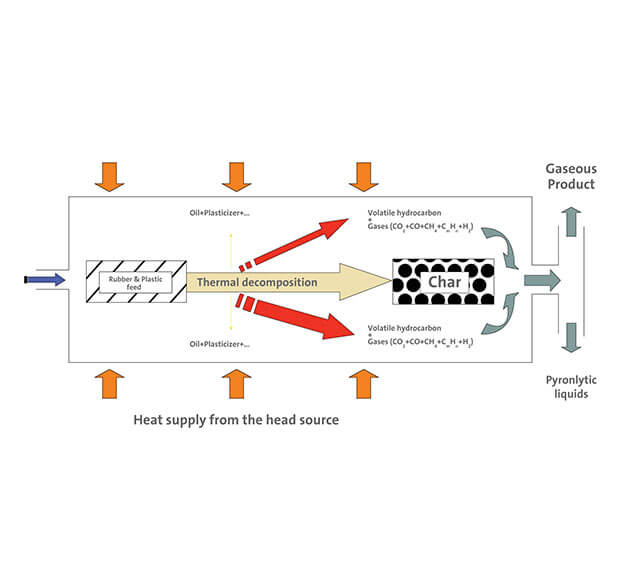

- Pyrolysis is the thermal decomposition of carbonaceous material in the absence of oxygen.

- The process is becoming attractive due to its greater flexibility to generate a combination of solid, liquid, and gaseous products in different proportions by varying the operating temperature and heating rate.

- Has a lower process temperature, thus lowering emissions of air pollutants.

- The pyrolysis process can accept a large variety of raw materials including industrial and domestic residues.

- Pyrolysis results in 100% repurposing of carbonaceous materials (rubber and plastic waste). In this way, not only wastes are processed, but also renewable resources are obtained.

Sustainability Aspects of Pyrolysis

Circular Economy-based waste management practice

Resource Recovery-based total

solution for waste

Brand protection

Avoid landfilling

Total environmentally friendly solution

Fully compliant and safety-driven

operation